MechNet is always striving to create new and unique labs to teach engineering technology. The new Labs coming sometime soon include: A single Cylinder engine Dynamometer, A Garett GTCP-95 APU as used in the Boeing 727 and a Brake Dynamometer.

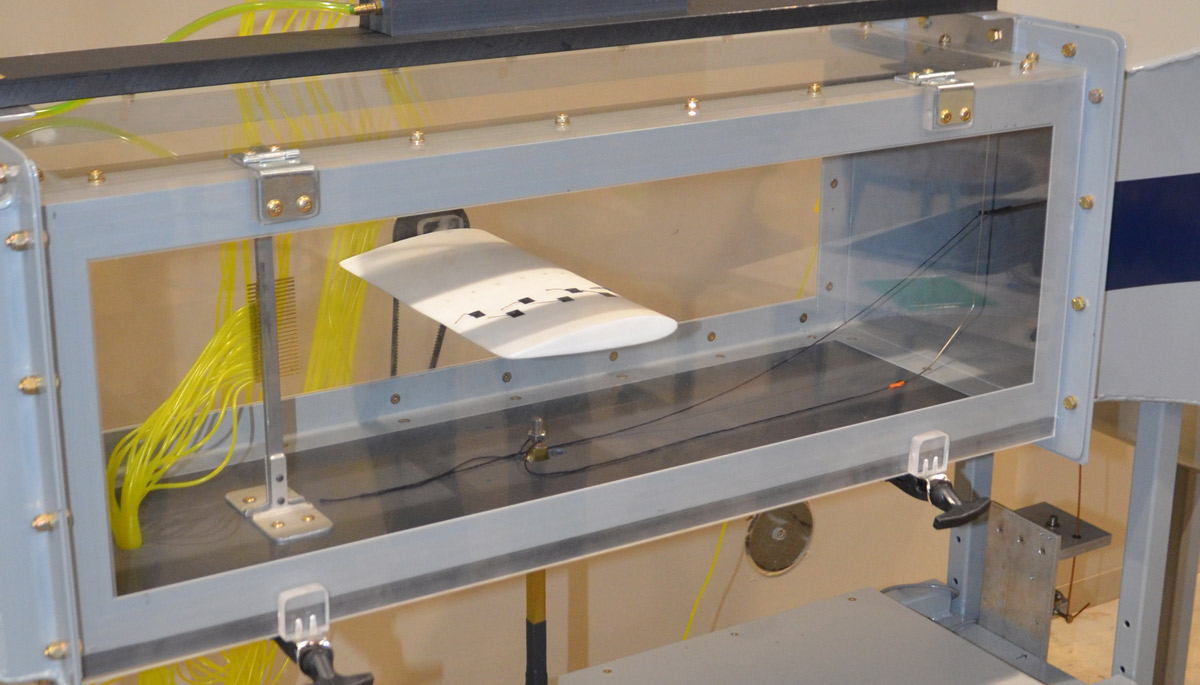

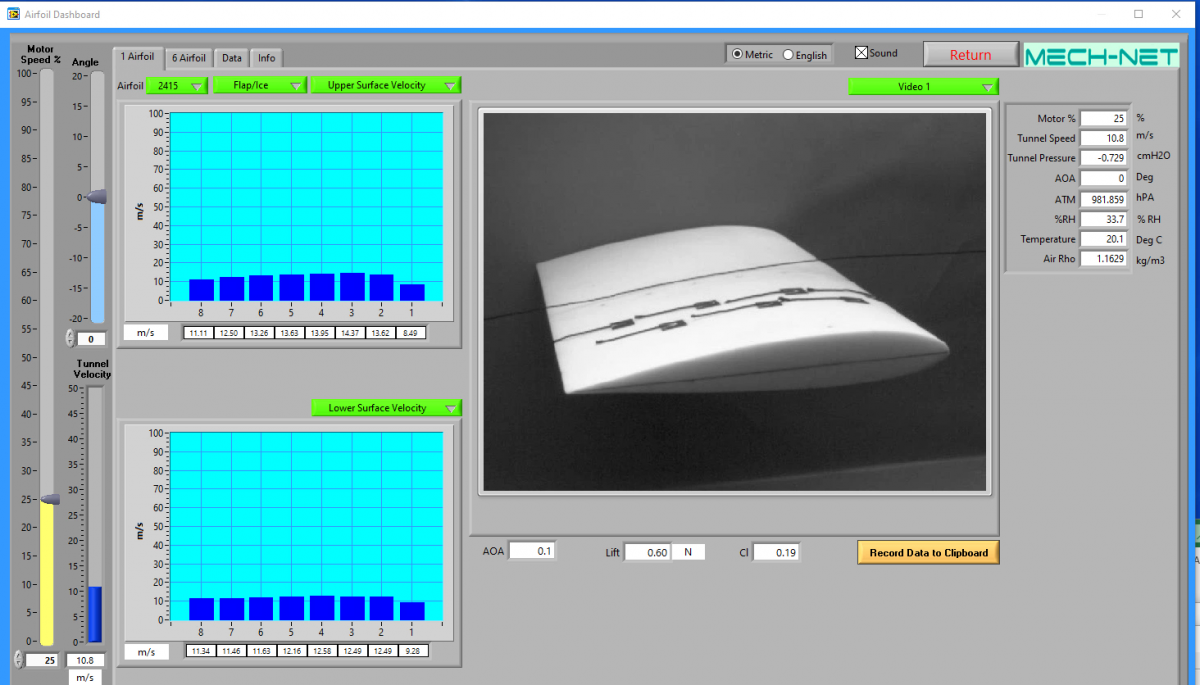

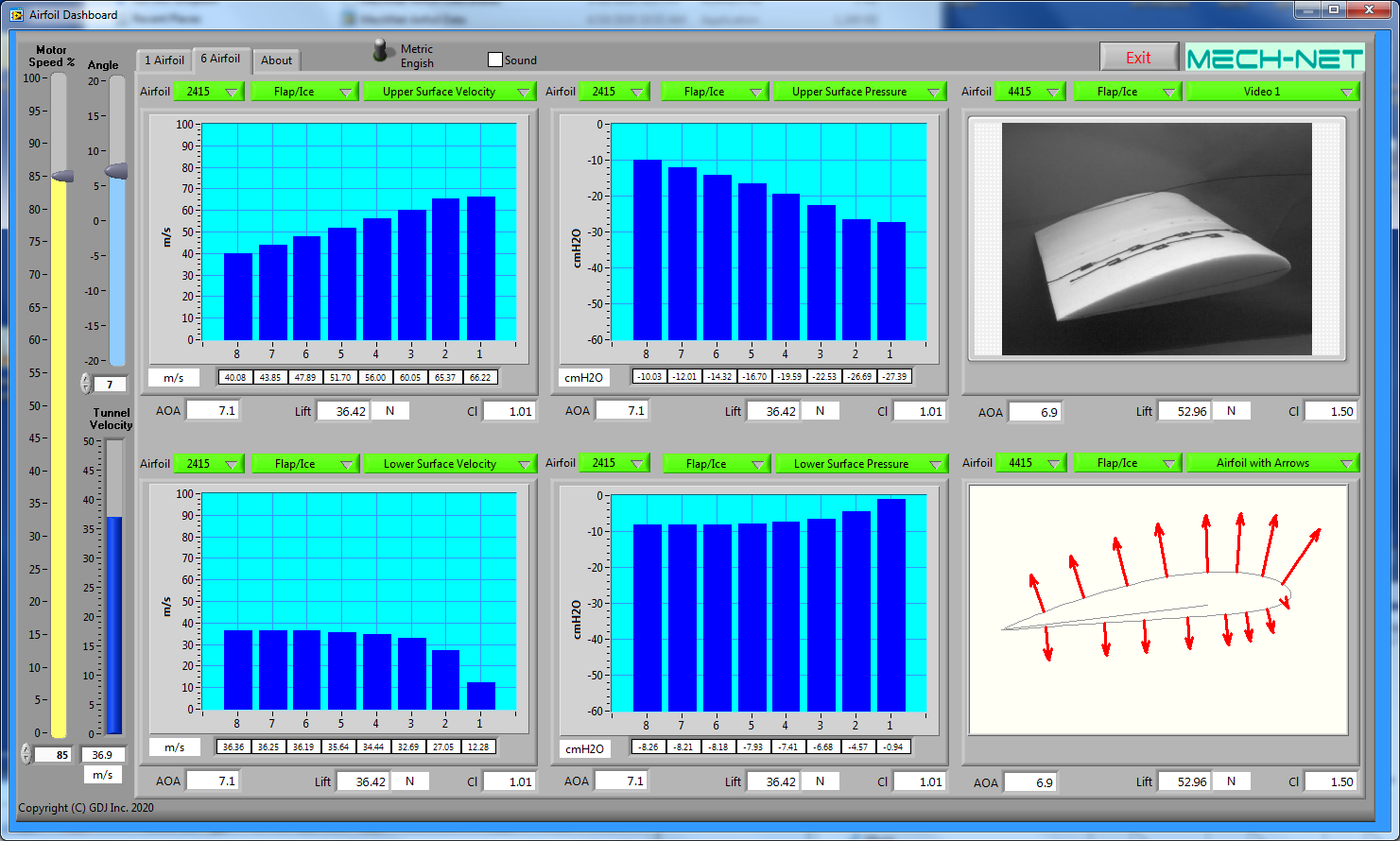

This is a very unique aerodynamics lab experiment in the fact that it is completely interactive. The student controls the wind tunnel velocity and the airfoil angle of attack. We have recorded the airfoil data and video from an actual wind tunnel test in progress.

The student will be able to select between 3 different airfoils. A NACA 0015,2415 & 4415 airfoil. They can also see how the lift data is affected by different 4 different flaps mounted on the airfoil and two different leading edge ice shapes. The data can be presented on one screen with a large video of the airfoil with tuffs to show the flow over the surface of the airfoil, or 6 data boxes which allows them to compare the lift data from different cambered airfoils.

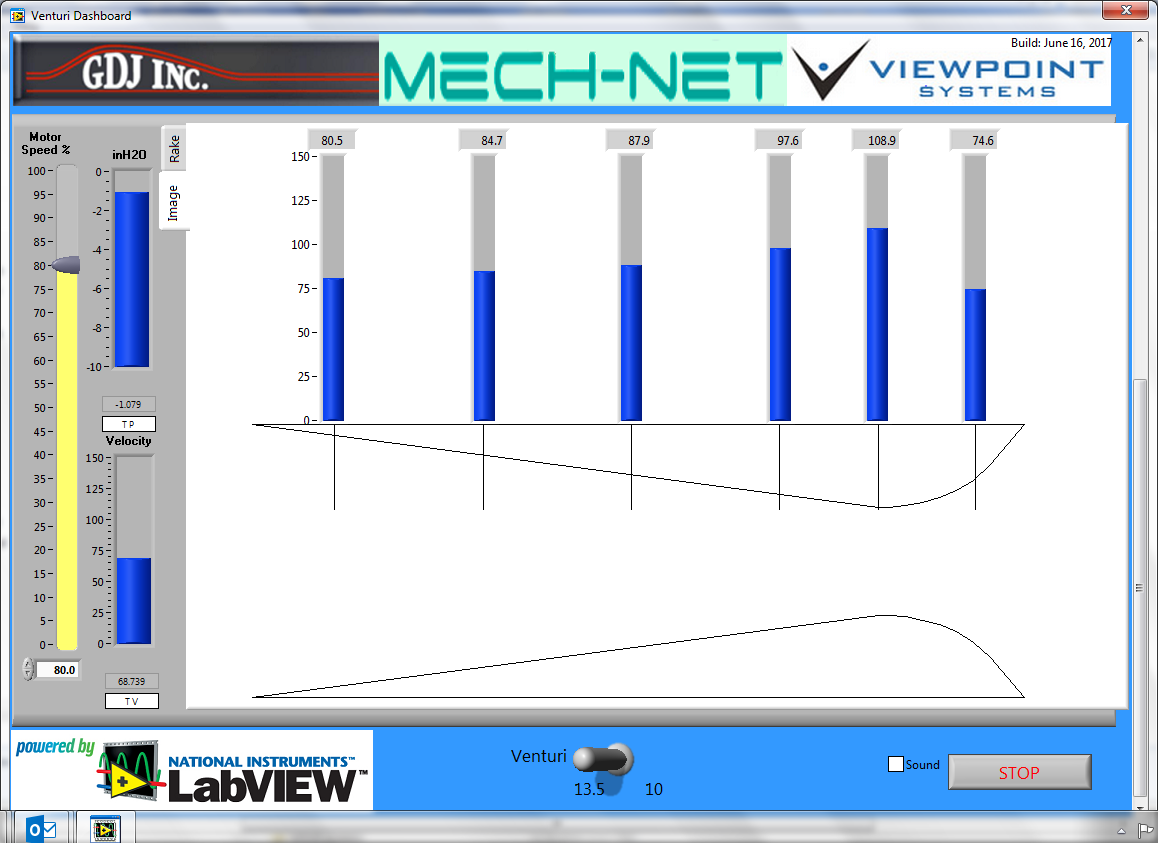

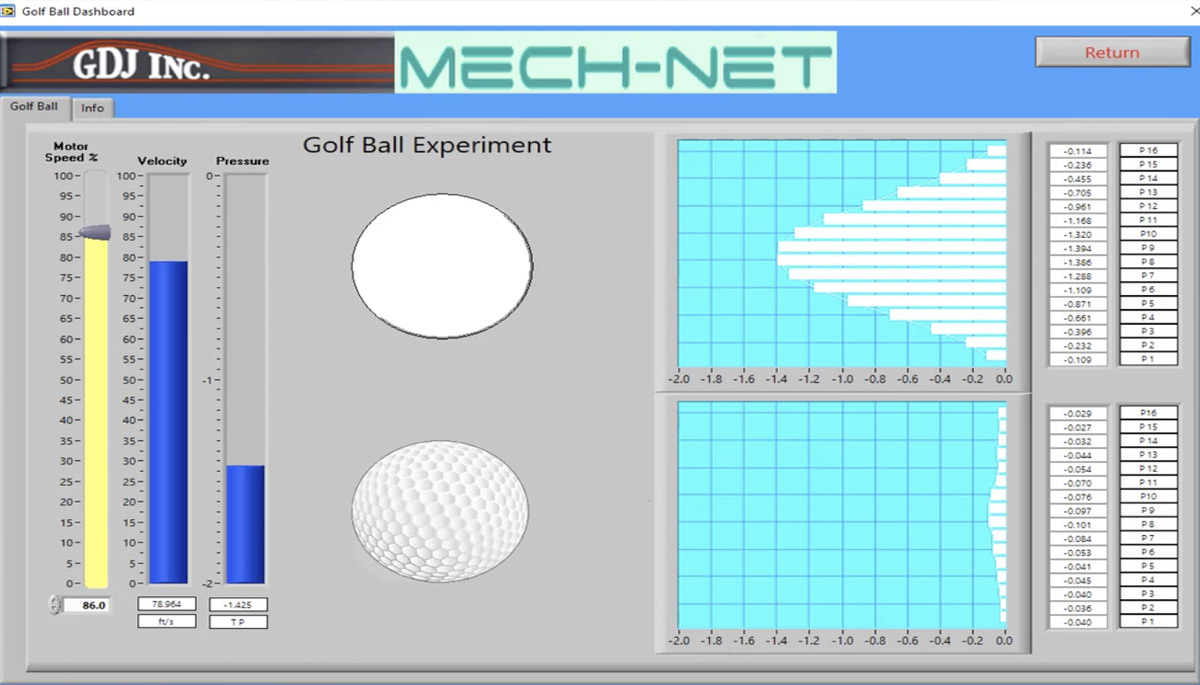

The Aero Lab also includes an airfoil with arrows which illustrated the lift on the airfoil by changing the length of an arrow on the surface where the data was taken. A Venturi experiment with two different Venturi shapes which allows them to do experiments with the Continuity Equation. This uses some very good hands on simple Algebraic Equations. The Golf Ball experiment which shows the data from a Dimpled and smooth Golf Ball to illustrate how the Dimples on Golf Ball actually reduce the drag on the ball.

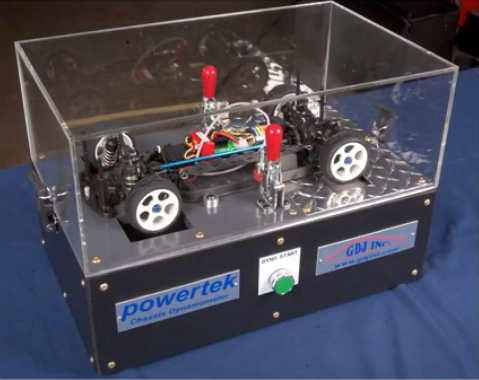

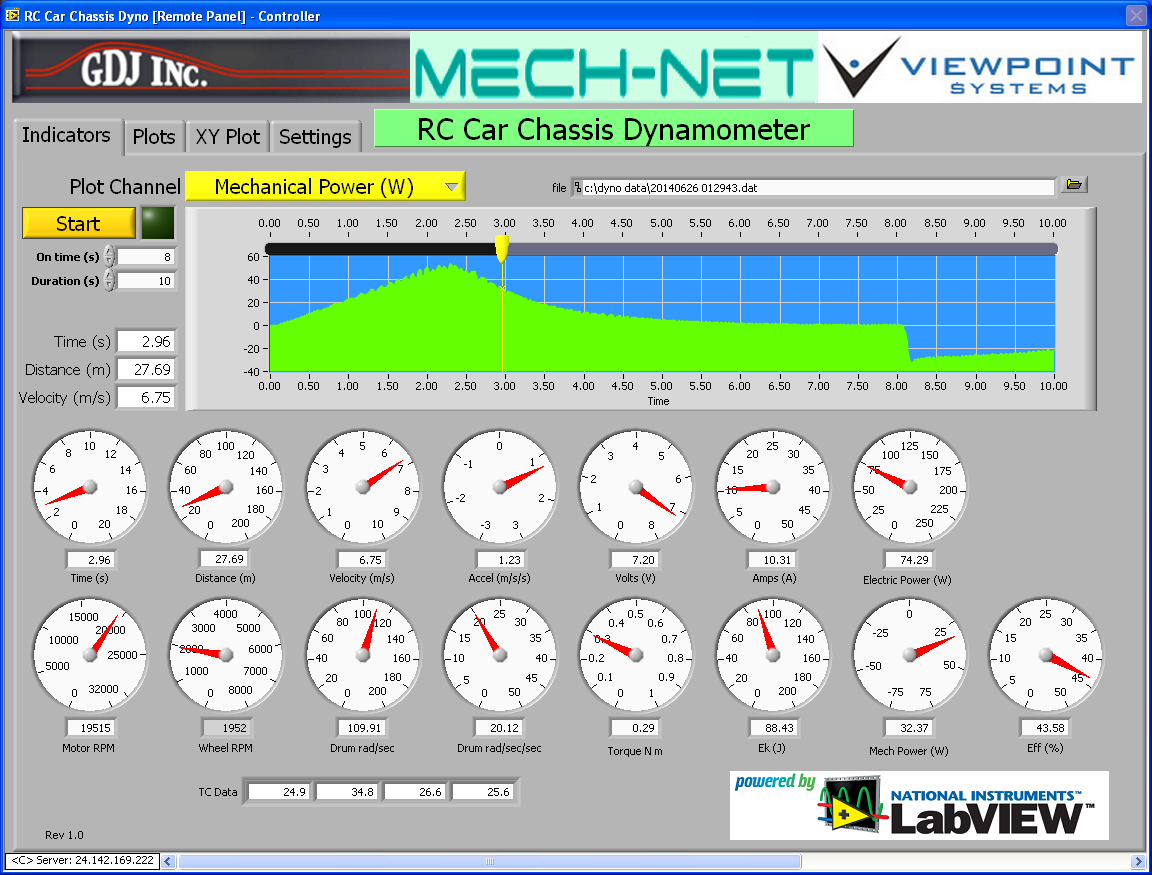

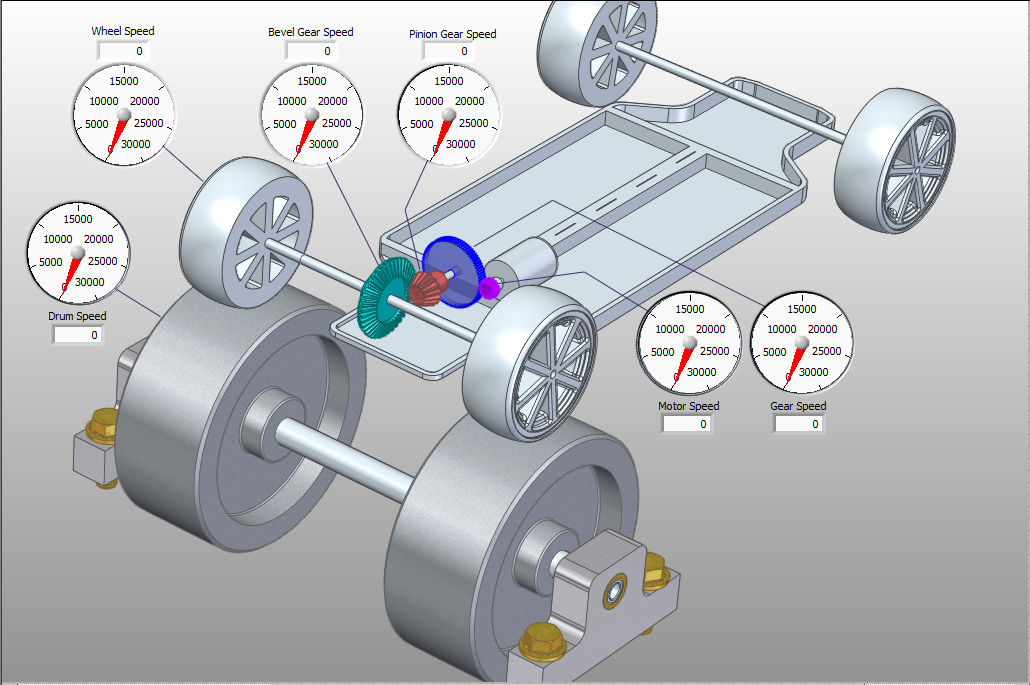

This experiment is accomplished by viewing the various forms of data such as Horsepower, Torque, Amperage and Wattage of a 1/10 scale RC car mounted on a chassis Dynamometer.

The student can select the data from dyno runs with 4 different motor gears, 3 different Voltage and 2 different amperages. This allows the students to see and hear the Dyno in action during a data run. They can also graph up 8 different runs to compare the data from different runs and select which type of data (Voltage, Amperage, Mechanical Power, Wattage Etc.) they want to display and compare. They can also do an X,Y Plot where they choose both the X and Y data.

There are also experiments with gear ratios where they can see the entire R/C car gear train in operation and see how changing the motor gear affect the speed of all the gears and wheels in the system. This is excellent hands on math with the lesson plans illustrating all the theory and formulas.

The MechNet Roller coaster Data Lab is in its final phases of development and will be ready for the Fall of 2022 classes.

This is a Recorded data lab using the MechNet roller coaster to obtain the data. This is an extremely unique Physics experiment for the student in the fact it provides extremely accurate data from a model steel roller coaster. The track is constructed in the same manner as the real thing and the car has been developed to provide very low rolling resistance.

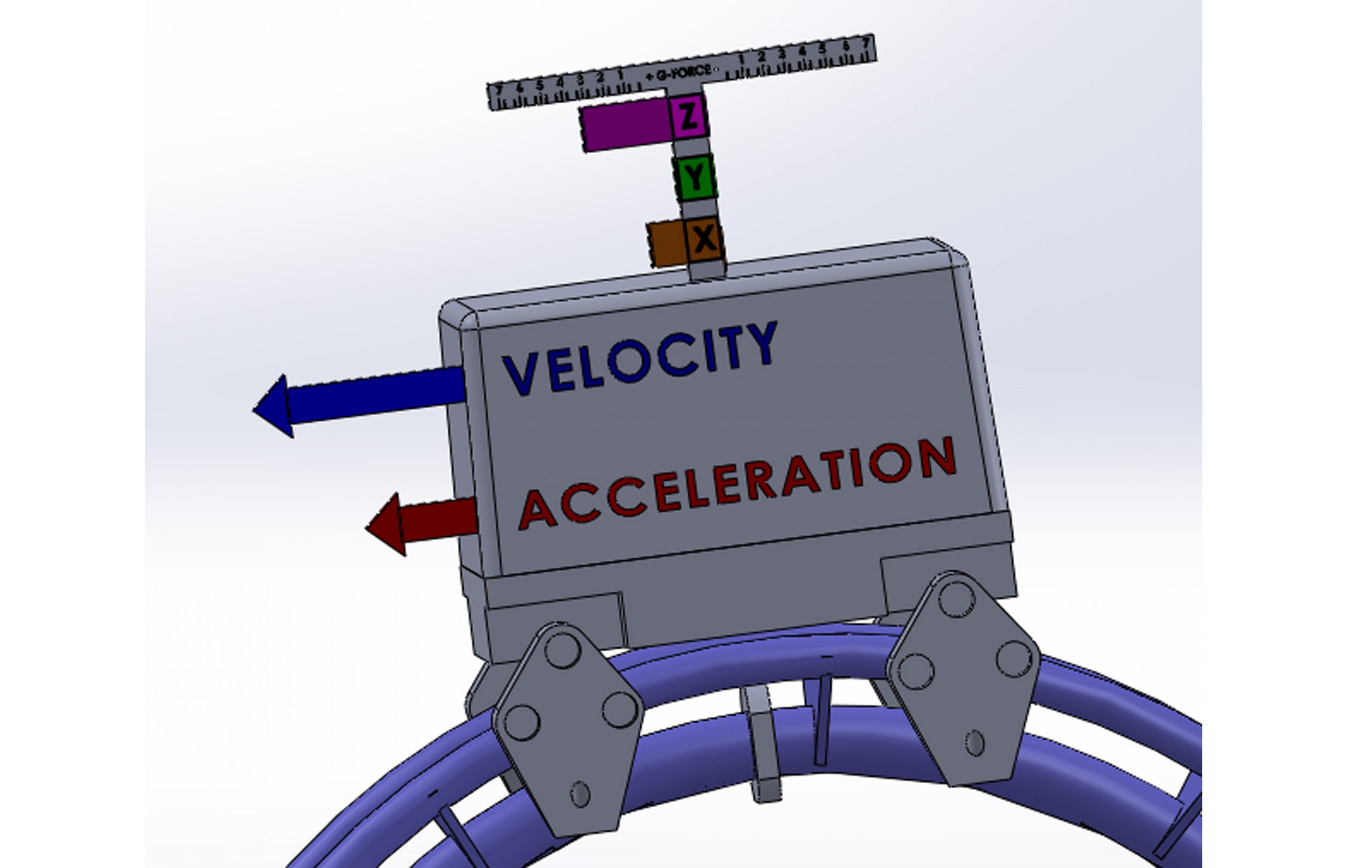

The velocity and acceleration data were obtained by placing industrial photo op sensor every 3 to 4” around the track. An array of 12 sensors were used to obtain the data from each section of the track at a time. To capture the data a National Instruments C-Rio Data acquisitions and LabVIEW FPGA software supplied the data at each sensor to an Excel Spreadsheet. I high end 3 axis accelerometer provides very accurate acceleration data.

To display the data the entire track and car were modeled in Solid Edge. An animation of the coaster car going around the track was created to provide an extremely visual approach so the student can see the what the data is at each section of the track, by arrows placed on the front of the car to show the Velocity and Acceleration. There also bar graphs above the car to display the g force. A separate screen display shows the Potential & Kinetic Energy of the car. The student can slow down or speed up the animation.

To make things even more interesting and to show why certain sections of the track are designed the way they are. We provided 3 different loop shapes and 5 different turn angles and shapes. The animation was created so the student evaluates each section of the track individually and can compare different sections side by side.